Description: eBay TMK lubricating oil anti-wear testing machine is specially customized for lubricating oil and its additive enterprises. Quickly and intuitively reflect the anti-wear and anti-friction performance of lubricating oil. This lubricating oil anti-wear testing machine adopts an integrated design to effectively reduce vibration and noise during work. Its main working parts are composed of a friction ring that rotates with the main shaft and a fixed friction column pressed on the friction ring. Under conditions, sliding friction occurs between the friction ring and the friction column. The lubricating oil anti-wear testing machine pressurizes the friction pair through an afterburner system composed of weights and levers, so that extremely high pressure is generated on the contact point. During the rotation of the friction ring, the wear of the friction column (experimental steel ball) is accelerated to observe and test apparatus for assessing the load-carrying capacity of lubricants. Under this specific lubricating condition, 1 minute of simulation test is equivalent to the wear amount of normal operation of general parts for 1 year. High-grade lubricating oil wears less under the same load, and the spindle speed does not drop or drops very little. Because the lubricating oil anti-wear testing machine can quickly and concisely reflect the anti-wear and anti-friction performance of lubricating oil, it is often used in the production, research and development and promotion of lubricating oil or anti-wear agent with better anti-wear performance. Before using this lubricating oil anti-wear testing machine, it should be noted that the domestic mains voltage is AC 220 volts, and ±5% is appropriate, the electrical system should be properly grounded, and the operator should have common sense of mechanical and electrical safety. This series of lubricating oil anti-wear testing machines have different models and prices according to different configurations. Instructions for use of DY-TMK anti-wear testing machine 1. Before each experiment, the friction wheel must be polished with whetstone dipped in ordinary oil, otherwise the correct effect of the experiment will be affected. 2, to do four tests, 1. The test of ordinary oil, 2. The test of oil with anti-wear agent added, 3. No oil test, 4. Repair test. The grinding wheel should be polished before each test, otherwise the test results will be inaccurate. The standard for grinding the grinding wheel is normal operation without noise. 3. The weight of the weight represents the pressure on the contact point, and the size of the wear scar of the steel ball represents the anti-wear property of the lubricating oil or anti-wear agent. Changing the number of weights is equivalent to changing the amount of pressure on the contacts. 4. The weight can be gently placed after the motor is running normally, and the time interval is about 3-5 seconds. Adding to the number of weights makes ordinary lubricating oil lose its lubricity and lock up until the engine stops rotating. At this time, the power should be turned off immediately to prevent the motor from burning. 5. Check the number of weights (lubricity) and observe the wear marks (wear resistance) of the friction block. 6. After the oil-free test, a certain amount of water can be added to the oil box, and then it is found that the machine is still running, showing the lubricating effect of the emulsified oil containing anti-wear agent. This is something that ordinary lubricating oil can't do. 7. This is just to show the lubricity and anti-wear properties of different lubricating oils under the same conditions. It is strictly forbidden to start the anti-wear testing machine under load! Precautions 1. Every time you do an experiment, you should turn the steel ball to a new position, clean the oil box, grind the grinding wheel, and wipe it with toilet paper, otherwise the experimental results will be inaccurate. 2. Turn off the power switch when the grinding wheel and the experimental steel ball are locked to avoid damage to the motor due to excessive load. 3. When loading weights, the speed should be uniform, generally adding one piece every 10 seconds. It can't be fast or slow, otherwise the test reproducibility is not good. 4. Before loading the weight, let the grinding wheel run without load in the oil to be tested for a while, so that the oil film can be fully formed. 5. This machine is mainly used for the comparison experiment of the anti-wear and extreme pressure properties of oil products. In order to protect the service life of the machine, please do not carry out overload and destructive experiments for a long time. 6. All models can be inserted into the thermometer probe to observe the oil temperature rise. 7. The equipment is a precision electronic instrument and cannot be disassembled arbitrarily, so as not to affect the normal use. DY-TMK type lubricating oil anti-wear testing machine supplementary expansion function There are three experimental functions to test the performance of oil products: 1. Test the anti-wear performance of the oil (record the size of the wear scar of the experimental steel ball, the motor current and the oil temperature change) (1): When the test oil is ordinary oil, place weights, the ordinary oil film on the grinding wheel breaks, the current increases, and the grinding wheel makes a harsh noise. At this time, the grinding wheel and the experimental steel ball are quickly locked (turn off the power immediately). Remove the experimental steel ball on the short lever to see the wear marks, the marks are large (3×6mm2), and the scratches are deep. (2): When the test oil is high-grade oil with anti-wear agent added, put the weights one by one, but the current does not increase, the grinding wheel and the experimental steel ball are not locked, the noise is very small to no, turn off the power, and watch the wear marks , the trace is very small (1.5 × 2.5mm2). The wear scar comparison test of different brands of similar oil can be carried out. 2. Test the extreme pressure performance of the oil (record the maximum number of weights placed during the experiment). When the grinding wheel is rubbed with the experimental steel ball, within a certain period of time (for example, 3 minutes), the maximum number of weights carried by the oil is the reflection of extreme pressure. When a small amount of weights are placed on ordinary oil, the oil film will be broken, and the grinding wheel and the steel ball will be locked. The high-grade oil with anti-wear extreme pressure agent can add up to 15-20 weights or even more weights, and the oil film still works well. Note: Grease (butter) can be tested by picking wood chips into the gap between the steel ball and the grinding wheel 3. The oil-free running test is to test the oil-free extreme pressure and anti-wear performance of the oil. Remove the oil box, do not grind the grinding wheel, the short rod steel balls remain in place, add weights one by one, and after a certain period of time, turn off the power supply, the wear marks on the experimental steel balls have not increased, indicating that an oil film has been formed on the metal surface. There are two commonly used experimental functions for the contact method between the grinding wheel and the experimental steel ball: 1. Point contact experiment function; The experimental steel ball is placed in parallel in the short lever notch to make vertical contact with the grinding wheel, and the test result shows that the wear scar is an approximate elliptical point. 2. Line contact experiment function The experimental steel ball is placed vertically in the short lever notch to make parallel contact with the grinding wheel, and the test result shows that the wear scar is in the shape of a line. This experimental method has a large friction surface, and the oil temperature changes obviously. At this time, insert the probe of the thermometer into the oil box and immerse it in the experimental oil, turn on the power, and the temperature rise performance of the oil can be seen most intuitively. Generally, the oil with strong anti-wear performance changes slowly and the oil temperature is low. Otherwise, the oil temperature will be high.

Price: 509.81 USD

Location: China

End Time: 2025-01-20T08:03:30.000Z

Shipping Cost: 322 USD

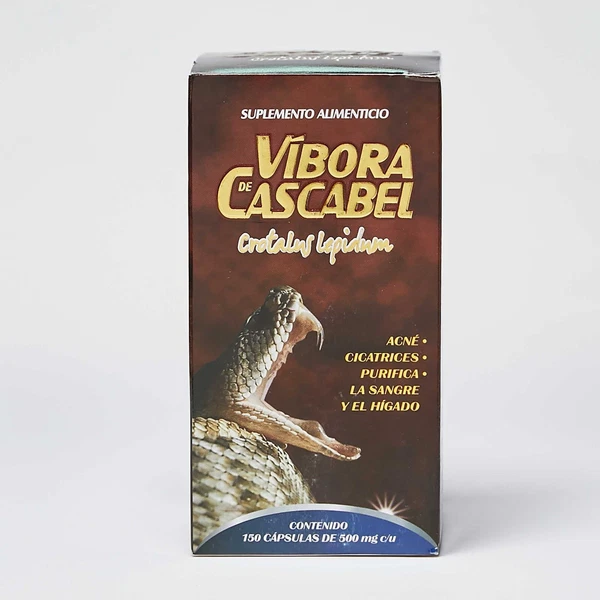

Product Images

Item Specifics

Restocking Fee: No

Return shipping will be paid by: Buyer

All returns accepted: Returns Accepted

Item must be returned within: 30 Days

Refund will be given as: Money back or replacement (buyer's choice)

Brand: Unbranded

Type: Anti-abrasion tester

Packing weight: 25KG

MPN: does not apply

Voltage / frequency: 220V / 50HZ/110V

Available Variations

Color: ELB-JYNM280 (pointer)

Price: 509.81 USD

Available Quantity: 1

Quantity Sold: 0

Color: ELB-JYNM280 (digital display)

Price: 564.67 USD

Available Quantity: 1

Quantity Sold: 0